The Repico® concept

Are you looking for a fast and reliable connection between pipes with specific media? Or do you have a leak?

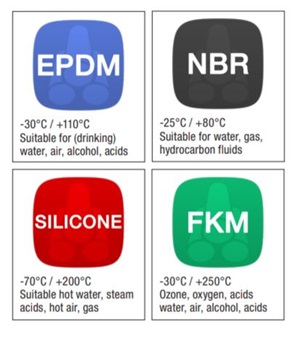

With the Repico® stainless steel coupling you can quickly and easily create a tensile-resistant or flexible connection between two pipes. In case of a leak, apply the Repico® repair coupling, only a few minutes installation time. Depending on the application, you can choose from the different rubber qualities EPDM, NBR, Silicone and FKM. Customization is also possible if desired.

AVK’s Repico® product program consists of stainless steel pipe couplings and repair couplings for pipe diameters from DN 15 up to DN 2000. The Repico® range offers a quick and simple connection solution for all pipes with possibility of angular deflection and easy handling due to the compact and light weight design. There are 2 types of couplings which operate on the same basic well proven principal. The Repico® grip restrains the pipe inside the coupling and the slip type that allows the pipe to move within the coupling.

Repico® grip (axially restraint)

The Repico® grip anchors in the pipe wall through grip rings, restraining the axial movement of the pipe in the coupling. Sealing to the pipe wall is done by the rubber sealing material inside the coupling.

Repico® slip (axially flexible)

The Repico® slip seals to the pipe wall by the rubber sealing material, as it has no grip rings the pipes need to be restrained outside the coupling. The expansion will be compensated through the allowable movement within the coupling. The Repico® slip/grip is a combination of the above mentioned types, one side slip, the other side grip.

Repair couplings

The main difference of a Repico® repair clamps or repair couplings compared to a Repico® coupling is that the rubber seal is not one piece and it has no grip rings. The split seal allows the clamp to be put around the pipe. They have the same progressive sealing as the grip and the slip. Some low pressure or special version might differ in sealing design.

Progressive seal & anchoring systems

The sealing material is encased in the stainless steel body and can be compressed by torqueing the bolts. With the grip type this also engages the teeth to “bite” into the pipe wall. By the internal pressure of the media the sealing material is pressed against the pipe wall and the grip ring is pushed outwards increasing their grip on the pipe wall. This is called progressive sealing and anchoring. The internal pressure of the media presses the Repico® seal against the pipe wall and the grip ring is pushing outwards increasing the grip on the pipe wall.

In-house production

The Repico® couplings and repair clamps are manufactured in our production location AVK Rewag in the Netherlands, equipped with the most modern production machines and test equipment. We are ISO 9001 and 14001 certified and use only the highest quality stainless steel and rubber parts / seals. AVK Rewag has over 40 years of experience in the manufacture of both standard and custom stainless steel products, which we sell in more than 40 countries.

AVK rubber manufacturing plant with unique sealing

The unique sealing is manufactured especially for the Repico® products in our rubber manufacturing plant. It is essential that the rubber components inside the Repico® couplings are of the highest quality to ensure a safe, watertight seal and trouble-free operation, even after many years without use. AVK GUMMI has developed rubber components for the water, natural gas, healthcare and food industries. By maintaining complete production control through our high-tech facilities and one of the world's most advanced mixing plants, we are able to offer unique rubber compounds of exceptional quality and uniformity. AVK’s rubber compounds have an excellent compression set, which means the ability to recover the original shape after having been compressed. Even after many years of operation, tiny pebbles, sand and other impurities will not affect the rubber surface or the tightness of the rubber.

Stainless steel and rubber qualities

The Repico® couplings are supplied as standard in stainless steel 316, Duplex and stainless steel 304 is available on request. Depending on the application, you can choose from the different rubber qualities EPDM, NBR, Silicone and FKM.

- EPDM Ethylene-Propylene-diene Monomer, according to EN 681-1, WRAS & W270 approved: is extremely suitable for water, hot water, oxidizing liquids and acids. Temperature reach -40°C to +120°C.

- NBR Nitrile-butadiene rubber (nitrile rubber), according to EN 682, is especially suitable for gas, (waste) water, animal and vegetable oil. Temperature reach -40°C to +100°C.

- FKM Fluorocarbon elastomer, has good resistance to mineral, vegetable and animal oils, fuels, many bases, acids and solvents. Temperature reach -30°C to +250°C.

- SILICONE, is especially suitable for steam. Temperature reach -70°C to +200°C.